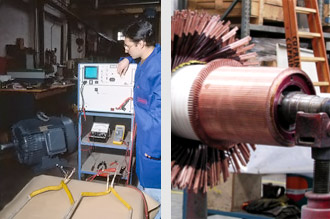

Workshop

Our workshop has been sized with functional feasibility for maximum enhancement of equipment. Incorporating to this factor our skilled workman ship and the specific expertise of our qualified staff, we are able to deal best with the maximum guarantee repair of electrical rotating machinery, from simple to complex motors and generators, high and low voltage AC/DC electric motors, wind turbine gearboxes, geared motors or gearboxes.

Workshop services

- Repair, Maintenance and rewinding of AC/DC low and high voltage electric motors up to 15 KV including Explosion proof motors

- Repair, Maintenance, and rewinding of AC/DC and wind generators

- Repair and maintenance of wind turbine gearboxes, geared-motors and gearboxes.

- Machining and rebuilding of mechanical parts and sleeve bearings.

- Core and squirrel cage repair and restack.

- Manufacture of formed coils and Roebel bars up to 15 kV

- Repair and maintenance of geared motors.

- Repair and maintenance of electric, hydraulic and vacuum pumps.

- Repair of transformers.

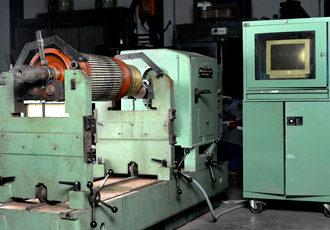

- Dynamic Balancing.

- Insulation resistance test ,EDA III test, Tan delta and partial discharges test , vibration analysis, videoscopic inspection, laser alignment, surge and hipot test, thermo graphic inspection, among others

- Load tests of motors and generators up to 1.200 K.W.

Our extensive experience as an official service for some of the leading manufacturers allows us to make modifications and adaptations of IEC or NEMA motors of any type and brand:

- Frequency and voltage change

- Reinforced bearing installation

- Constructive form modification

- Thermal sensors wiring

- Space heater installation

- Encoders and pulse generators installation

- Forced Ventilation installation

- Electric brake installation

- Power increase